The current position:Home > Production casting machine series > Dl-lyj-24se1000 coater

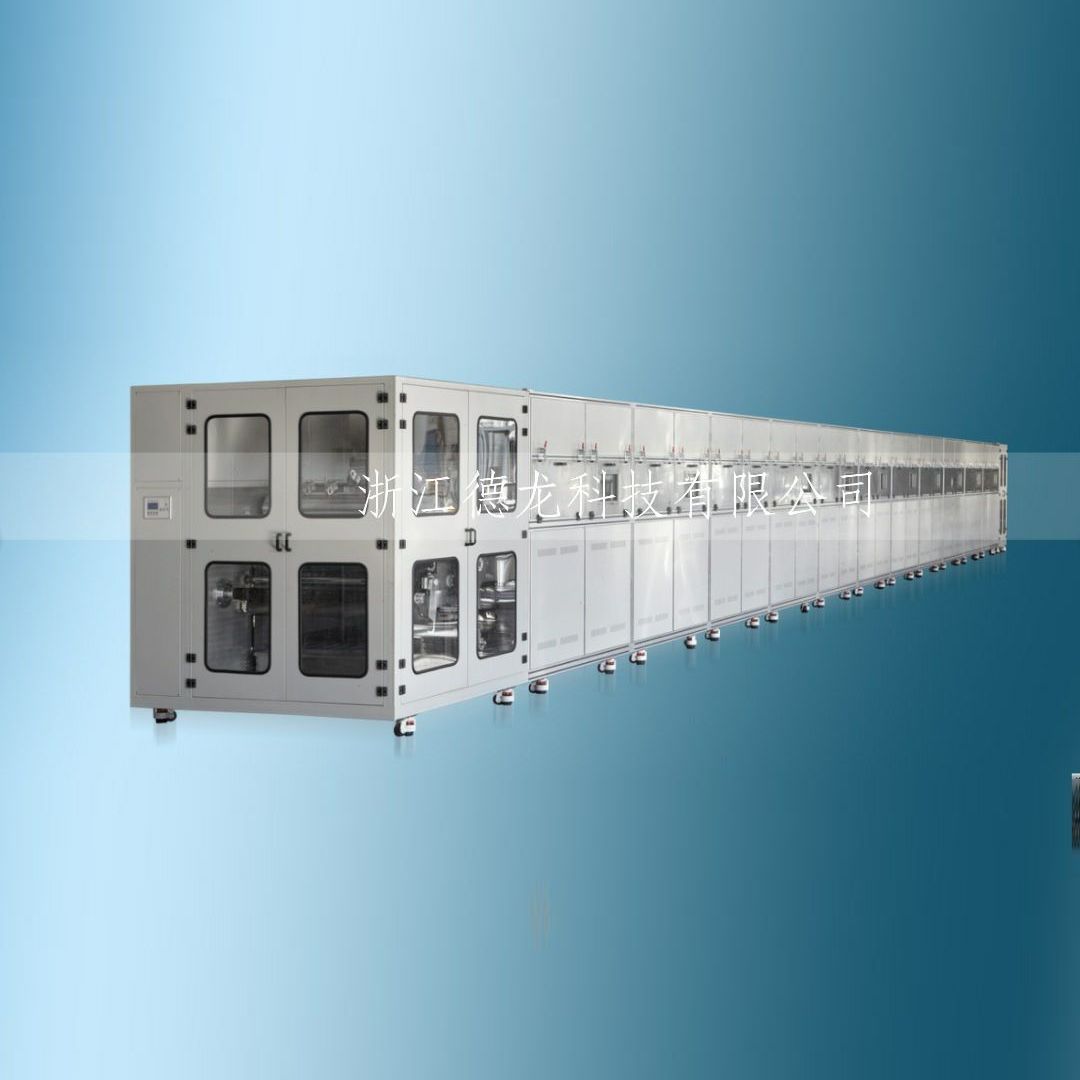

Dl-lyj-24se1000 coater

- product description

- Product Brief

The dl-lyj-24se1000 casting machine is our most advanced product, which is suitable for the highest production requirements. Advanced servo knife adjustment, servo tension, fast deviation correction and efficient drying system make them very suitable for 25-1200um porcelain belt production. The whole process from feeding to coiling is highly automatic. The use, operation and maintenance of the equipment are convenient, with beautiful appearance and excellent after-sales service.

technical parameter

1) equipment specification: 29000 * 1800 * 2000mm (L * w * h)

2) carrier material: PET film (100-188um)

3) casting viscosity: 500-10000mpa. S

4) scraper clearance: 10-4500 ¦Ì M

5) casting width: 1000mm (effective width 1050mm)

6) casting speed: 0.02-6.0 (M / min)

7) scraper height: 5-4500 ¦Ì M

8) thickness of porcelain belt: suitable for 25-1500um

9) tool adjustment accuracy: 0.001mm

10) knife adjustment control: closed loop control of motor plus ball screw with electronic dial indicator

11) thickness accuracy: less than ¡À 5% of belt thickness

12) floor control temperature: room temperature ~ 100 ¡ã C

13) drying area: Area 1 ------ hot air circulation of upper air nozzle of four meters + heating of four sections of base plate

Zone 2 - upper air nozzle hot air circulation + four section bottom plate heating

Zone 3 - four meter upper nozzle hot air circulation + four section bottom plate heating

Zone 4 - upper air nozzle hot air circulation + four section bottom plate heating

Zone 5 - four meter upper nozzle hot air circulation + four section bottom plate heating

Zone 6 - four meter upper nozzle hot air circulation + four section bottom plate heating

(each section is attached with temperature monitoring and display, which can be adjusted in real time)

14) automatic feeding system: fully automatic feeding, PID control flow, control accuracy ¡À 0.1mm

15) liquid level height: 0-40.0mm

16) ceramic belt trimming and cutting: imported alloy steel blade

17) electrostatic precipitator: 4 sets

18) tension control: the servo motor (Panasonic) controls the tension, and the baseband operation has no fluctuation

19) working voltage: 380V 50 / 60Hz

Product characteristics

High configuration of imported components

12 inch Siemens color touch screen, human-computer friendly interface, fully integrated interface display and control of heating, speed, liquid level, etc. Siemens PLC control, stable performance, high precision, in line with industrial automation control standards;

Servo (Panasonic) motor controls tension to achieve unique constant speed technology and no fluctuation in operation;

Automatic continuous feeding system liquid level control. Deviation ¡À 0.1mm;

Advanced laser displacement sensor controls liquid level dose;

Full automatic tool adjustment system, high-precision clearance setting and control, with an accuracy of ¡À 0.001mm;

Scraper height automatic zero calibration, Taiwan digital dial indicator display, touch screen control scraper height;

High precision servo (Panasonic) motor controls the casting, with the speed of 0.02-6m/min;

6 sections of inlet air circulation heating control, each section of inlet air flow up to 900m3 / h;

Exhaust air circulation system, exhaust air is uniform, flow frequency conversion speed control, exhaust air each area is controlled separately;

24 sections of bottom plate heating and temperature area, each section of bottom plate temperature is controlled separately, with control accuracy of ¡À 0.1C ¡ã;

The casting drying channel is equipped with front light background and rear light background detection, which is easy to detect the current situation of fine casting by comparison;

Fast baseband deviation correction, adjust the time for 1s, reach the center of membrane belt in an instant, and make the winding edge neat;

Pneumatic alloy knife trimming, convenient and adjustable knife width and spacing.

Unique and convenient technology:

The whole equipment shall be closed with door frame to achieve dust-free;

High density filter is adopted for air intake to achieve dust-free space;

The feed is provided with a slurry filter to prevent particles from affecting the casting quality;

The whole machine adopts the national standard thickened aluminum profile, horizontal, and the gap reaches the high precision and consistency;

Set transparent glass windows on the door cover of each drying area to observe the internal conditions;

There is a waste collection box, which is clean and tidy without debris after trimming;

The unique scraper cutting technology ensures the casting precision, and the blade precision reaches 0.1um;

Each transition roll shall be finished and each link shall not be simplified;

All aluminum rollers are hard oxidized, and steel rods are hard chrome plated or stainless steel;

Thickened aluminum alloy shall be used for the internal materials of spray coating accessories to ensure the service life of the accessories;

Food grade stainless steel is used as the material of drying channel, which is completely sealed and insulated to reduce energy consumption;

Product Brief

The dl-lyj-24se1000 casting machine is our most advanced product, which is suitable for the highest production requirements. Advanced servo knife adjustment, servo tension, fast deviation correction and efficient drying system make them very suitable for 25-1200um porcelain belt production. The whole process from feeding to coiling is highly automatic. The use, operation and maintenance of the equipment are convenient, with beautiful appearance and excellent after-sales service.

technical parameter

1) equipment specification: 29000 * 1800 * 2000mm (L * w * h)

2) carrier material: PET film (100-188um)

3) casting viscosity: 500-10000mpa. S

4) scraper clearance: 10-4500 ¦Ì M

5) casting width: 1000mm (effective width 1050mm)

6) casting speed: 0.02-6.0 (M / min)

7) scraper height: 5-4500 ¦Ì M

8) thickness of porcelain belt: suitable for 25-1500um

9) tool adjustment accuracy: 0.001mm

10) knife adjustment control: closed loop control of motor plus ball screw with electronic dial indicator

11) thickness accuracy: less than ¡À 5% of belt thickness

12) floor control temperature: room temperature ~ 100 ¡ã C

13) drying area: Area 1 ------ hot air circulation of upper air nozzle of four meters + heating of four sections of base plate

Zone 2 - upper air nozzle hot air circulation + four section bottom plate heating

Zone 3 - four meter upper nozzle hot air circulation + four section bottom plate heating

Zone 4 - upper air nozzle hot air circulation + four section bottom plate heating

Zone 5 - four meter upper nozzle hot air circulation + four section bottom plate heating

Zone 6 - four meter upper nozzle hot air circulation + four section bottom plate heating

(each section is attached with temperature monitoring and display, which can be adjusted in real time)

14) automatic feeding system: fully automatic feeding, PID control flow, control accuracy ¡À 0.1mm

15) liquid level height: 0-40.0mm

16) ceramic belt trimming and cutting: imported alloy steel blade

17) electrostatic precipitator: 4 sets

18) tension control: the servo motor (Panasonic) controls the tension, and the baseband operation has no fluctuation

19) working voltage: 380V 50 / 60Hz

Product characteristics

High configuration of imported components

12 inch Siemens color touch screen, human-computer friendly interface, fully integrated interface display and control of heating, speed, liquid level, etc. Siemens PLC control, stable performance, high precision, in line with industrial automation control standards;

Servo (Panasonic) motor controls tension to achieve unique constant speed technology and no fluctuation in operation;

Automatic continuous feeding system liquid level control. Deviation ¡À 0.1mm;

Advanced laser displacement sensor controls liquid level dose;

Full automatic tool adjustment system, high-precision clearance setting and control, with an accuracy of ¡À 0.001mm;

Scraper height automatic zero calibration, Taiwan digital dial indicator display, touch screen control scraper height;

High precision servo (Panasonic) motor controls the casting, with the speed of 0.02-6m/min;

6 sections of inlet air circulation heating control, each section of inlet air flow up to 900m3 / h;

Exhaust air circulation system, exhaust air is uniform, flow frequency conversion speed control, exhaust air each area is controlled separately;

24 sections of bottom plate heating and temperature area, each section of bottom plate temperature is controlled separately, with control accuracy of ¡À 0.1C ¡ã;

The casting drying channel is equipped with front light background and rear light background detection, which is easy to detect the current situation of fine casting by comparison;

Fast baseband deviation correction, adjust the time for 1s, reach the center of membrane belt in an instant, and make the winding edge neat;

Pneumatic alloy knife trimming, convenient and adjustable knife width and spacing.

Unique and convenient technology:

The whole equipment shall be closed with door frame to achieve dust-free;

High density filter is adopted for air intake to achieve dust-free space;

The feed is provided with a slurry filter to prevent particles from affecting the casting quality;

The whole machine adopts the national standard thickened aluminum profile, horizontal, and the gap reaches the high precision and consistency;

Set transparent glass windows on the door cover of each drying area to observe the internal conditions;

There is a waste collection box, which is clean and tidy without debris after trimming;

The unique scraper cutting technology ensures the casting precision, and the blade precision reaches 0.1um;

Each transition roll shall be finished and each link shall not be simplified;

All aluminum rollers are hard oxidized, and steel rods are hard chrome plated or stainless steel;

Thickened aluminum alloy shall be used for the internal materials of spray coating accessories to ensure the service life of the accessories;

Food grade stainless steel is used as the material of drying channel, which is completely sealed and insulated to reduce energy consumption;

Slit head

Slit head