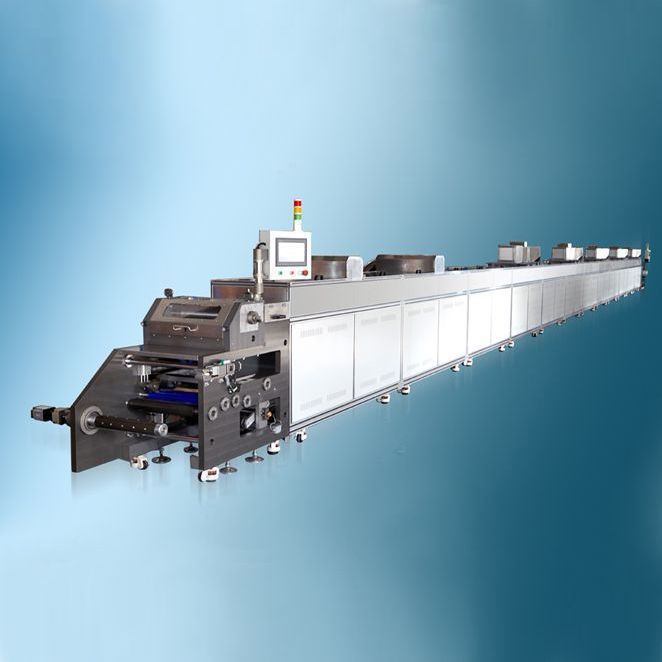

DL-LYJ-24MU350 Casting machine

- product description

technical parameter

1) Equipment specifications: 26800*1000*1350mm (length*width*height)

2) Material of carrier tape: PET film (38-188um)

3) Casting width: 350MM

4) Casting speed: 0.02-3.0 (M/min)

5) Scraper height: 5¡«3500¦Ìm

6) Casting thickness: suitable for 20-1500um

7) Scraper accuracy: 0.05um

8) Knife adjustment control: manual control of screw with dial indicator

9) Thickness accuracy: ¡À(1um+2% with thickness)

10) Baseboard control temperature: room temperature ~ 100¡æ (¡À0.1¡æ), the maximum temperature of the inlet air is 100¡æ

11) Drying area: The first area------4 section of floor heating + air circulation

The second zone ------4 section floor heating + hot air circulation

The third zone ------4 sections of floor heating + hot air circulation

The fourth zone ------4 section floor heating + hot air circulation

Fifth zone------4 section floor heating + hot air circulation

The sixth zone ------4 section floor heating + hot air circulation

12) Automatic feeding system: fully automatic feeding, PID control flow, control accuracy ¡À0.1mm

13) Liquid level height: 0-40.0mm

14) Trimming and slitting: alloy steel blade

15) Electrostatic dust removal: 4 sets

16) Tension control: the servo motor controls the tension, and the baseband runs without fluctuation

17) Working voltage: 380V 50/60HZ

Features

High configuration of imported components

l 10-inch Siemens color touch screen, human-machine friendly interface, fully integrated interface display and control of heating, speed, liquid level and so on. Using Siemens PLC control, stable performance, high precision, in line with industrial automation control standards;

Ø The servo motor controls the tension to achieve a unique constant speed technology, without fluctuations in operation;

Ø Liquid level control of automatic continuous feeding system. Deviation ¡À0.1mm;

Ø Advanced laser displacement sensor to control liquid level dose;

Ø Fully automatic knife adjustment system, high-precision gap setting and control, accuracy up to ¡À0.001mm;

Ø High precision servo motor control casting, speed can reach 0.02-3m/min;

Ø Exhaust circulation system, uniform exhaust, variable frequency speed control of flow rate, separate control of exhaust air in each zone;

Ø 24 sections of floor heating and temperature zone, each section of floor temperature is controlled separately, the control accuracy is ¡À0.1C¡ã;

Ø Casting with headlight background detection, it is easy to compare the status of subtle casting;

Ø Quick baseband correction, adjust the time 1S, instantaneously reach the center of the film belt, make the winding edge neat;

Ø Pneumatic alloy knife trimming, easy to adjust the width of the knife width.

Unique and convenient process:

Ø The casting head is fully enclosed to achieve a dust-free space, ensuring that the casting is dust-free;

Ø The machine adopts profile, level, and the gap reaches high precision and consistency;

Ø Set transparent glass windows on the door cover of each drying area to observe the internal conditions;

Ø After finishing each transition roll, not every link is simplified.

Ø Thick aluminum alloy is used for the internal materials of the paint-coated accessories to ensure the practical life of the accessories;

Ø The oven is fully enclosed and thermally insulated to reduce energy consumption;

technical parameter

1) Equipment specifications: 26800*1000*1350mm (length*width*height)

2) Material of carrier tape: PET film (38-188um)

3) Casting width: 350MM

4) Casting speed: 0.02-3.0 (M/min)

5) Scraper height: 5¡«3500¦Ìm

6) Casting thickness: suitable for 20-1500um

7) Scraper accuracy: 0.05um

8) Knife adjustment control: manual control of screw with dial indicator

9) Thickness accuracy: ¡À(1um+2% with thickness)

10) Baseboard control temperature: room temperature ~ 100¡æ (¡À0.1¡æ), the maximum temperature of the inlet air is 100¡æ

11) Drying area: The first area------4 section of floor heating + air circulation

The second zone ------4 section floor heating + hot air circulation

The third zone ------4 sections of floor heating + hot air circulation

The fourth zone ------4 section floor heating + hot air circulation

Fifth zone------4 section floor heating + hot air circulation

The sixth zone ------4 section floor heating + hot air circulation

12) Automatic feeding system: fully automatic feeding, PID control flow, control accuracy ¡À0.1mm

13) Liquid level height: 0-40.0mm

14) Trimming and slitting: alloy steel blade

15) Electrostatic dust removal: 4 sets

16) Tension control: the servo motor controls the tension, and the baseband runs without fluctuation

17) Working voltage: 380V 50/60HZ

Features

High configuration of imported components

l 10-inch Siemens color touch screen, human-machine friendly interface, fully integrated interface display and control of heating, speed, liquid level and so on. Using Siemens PLC control, stable performance, high precision, in line with industrial automation control standards;

Ø The servo motor controls the tension to achieve a unique constant speed technology, without fluctuations in operation;

Ø Liquid level control of automatic continuous feeding system. Deviation ¡À0.1mm;

Ø Advanced laser displacement sensor to control liquid level dose;

Ø Fully automatic knife adjustment system, high-precision gap setting and control, accuracy up to ¡À0.001mm;

Ø High precision servo motor control casting, speed can reach 0.02-3m/min;

Ø Exhaust circulation system, uniform exhaust, variable frequency speed control of flow rate, separate control of exhaust air in each zone;

Ø 24 sections of floor heating and temperature zone, each section of floor temperature is controlled separately, the control accuracy is ¡À0.1C¡ã;

Ø Casting with headlight background detection, it is easy to compare the status of subtle casting;

Ø Quick baseband correction, adjust the time 1S, instantaneously reach the center of the film belt, make the winding edge neat;

Ø Pneumatic alloy knife trimming, easy to adjust the width of the knife width.

Unique and convenient process:

Ø The casting head is fully enclosed to achieve a dust-free space, ensuring that the casting is dust-free;

Ø The machine adopts profile, level, and the gap reaches high precision and consistency;

Ø Set transparent glass windows on the door cover of each drying area to observe the internal conditions;

Ø After finishing each transition roll, not every link is simplified.

Ø Thick aluminum alloy is used for the internal materials of the paint-coated accessories to ensure the practical life of the accessories;

Ø The oven is fully enclosed and thermally insulated to reduce energy consumption;

Slit head

Slit head