M series warm isostatic press

- product description

The warm isostatic press is used to seal multiple layers of film in vacuum packaging bags, which are then placed inside a chamber. A servo hydraulic mechanism is used to move the chamber and the material into a hot water sealing cylinder environment. The high-pressure boosting pump increases the water pressure inside the chamber to a high level, and temperature and pressure are evenly applied to the components inside the pressure cylinder. This equipment is used for pressing multiple layers of ceramic capacitors and other films to enhance the physical and electrical properties of the products.

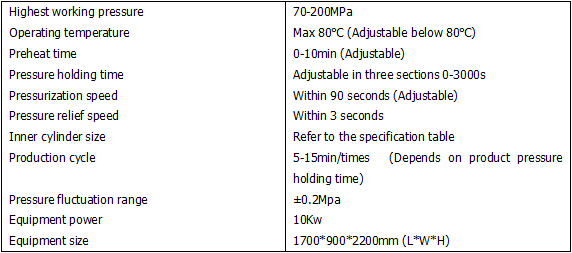

Technical reference

10-inch color LCD touchscreen, electrical control system is Siemens PLC programmable control.

10-inch color LCD touchscreen, electrical control system is Siemens PLC programmable control.

Super quiet 2KW servo motor closed-loop control system controls the chamber's rise and fall (low noise, energy-saving, stable, safe).

After loading, it can automatically complete the entire process of preheating, pre-pressing, pressurization, pressure holding, and pressure relief.

Slit head

Slit head